CerMark Technical Support – CerMark Sales

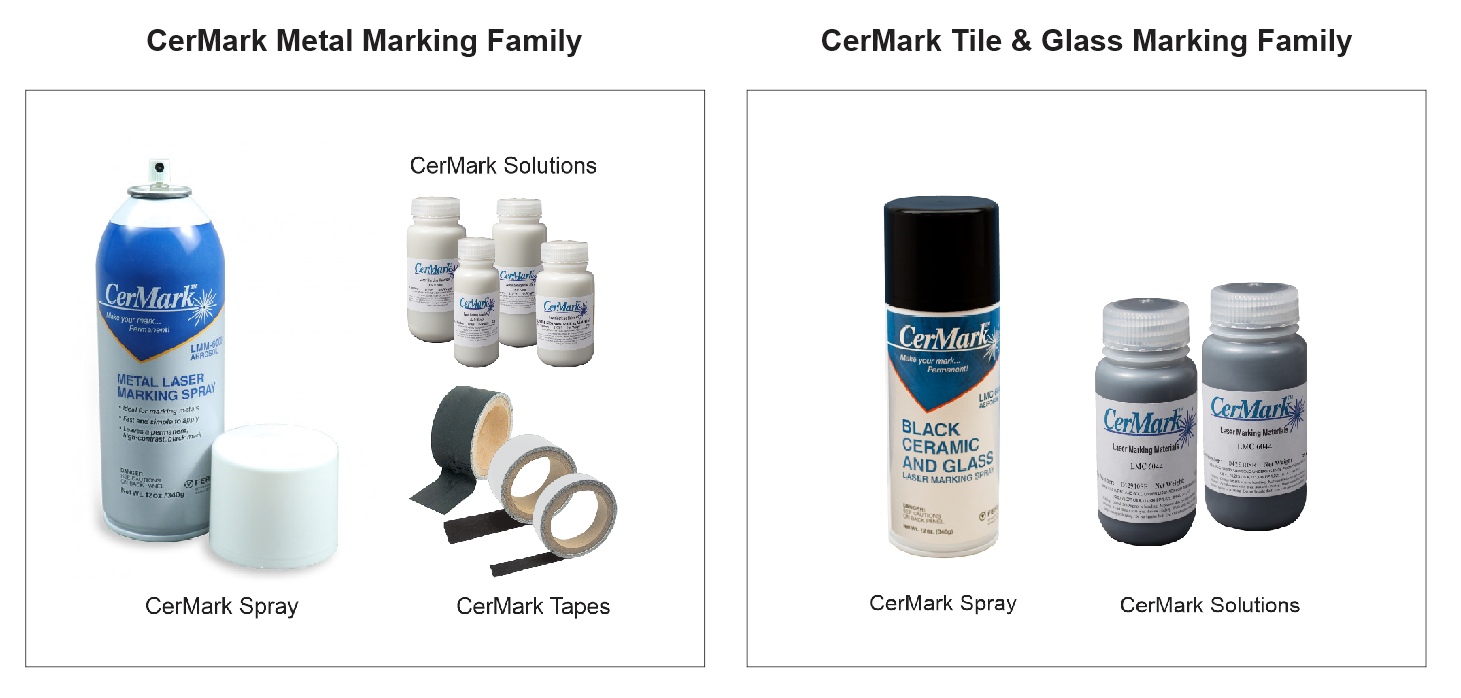

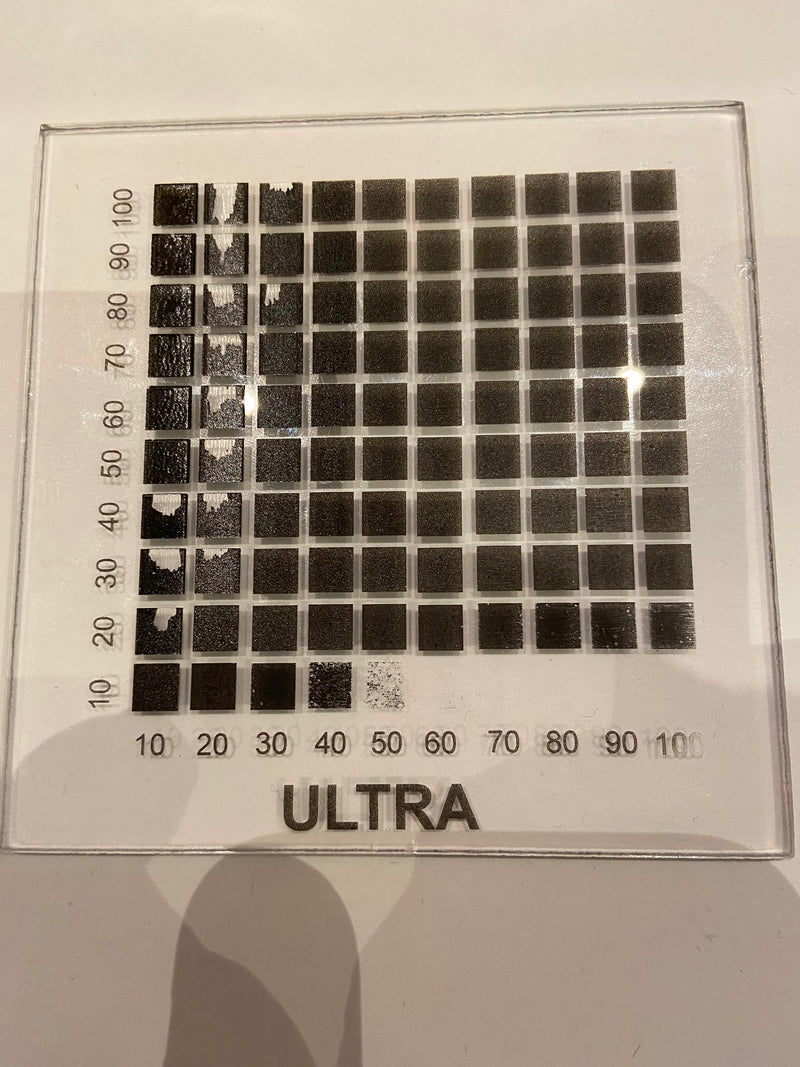

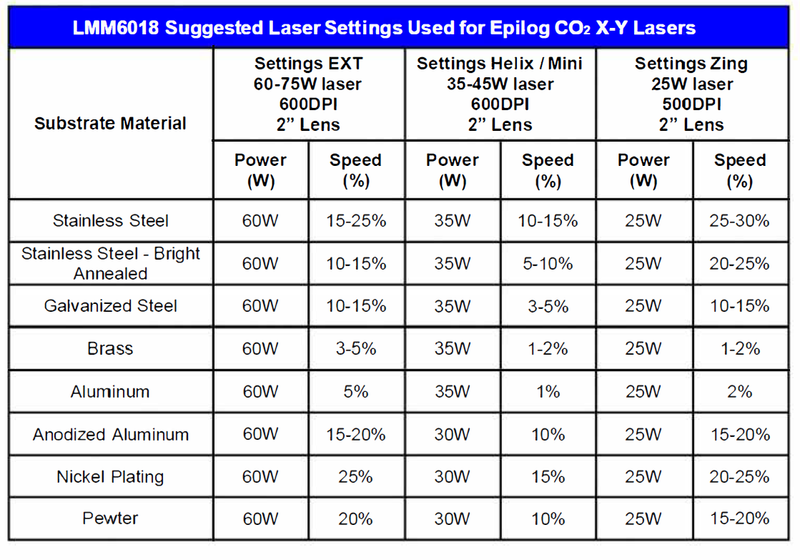

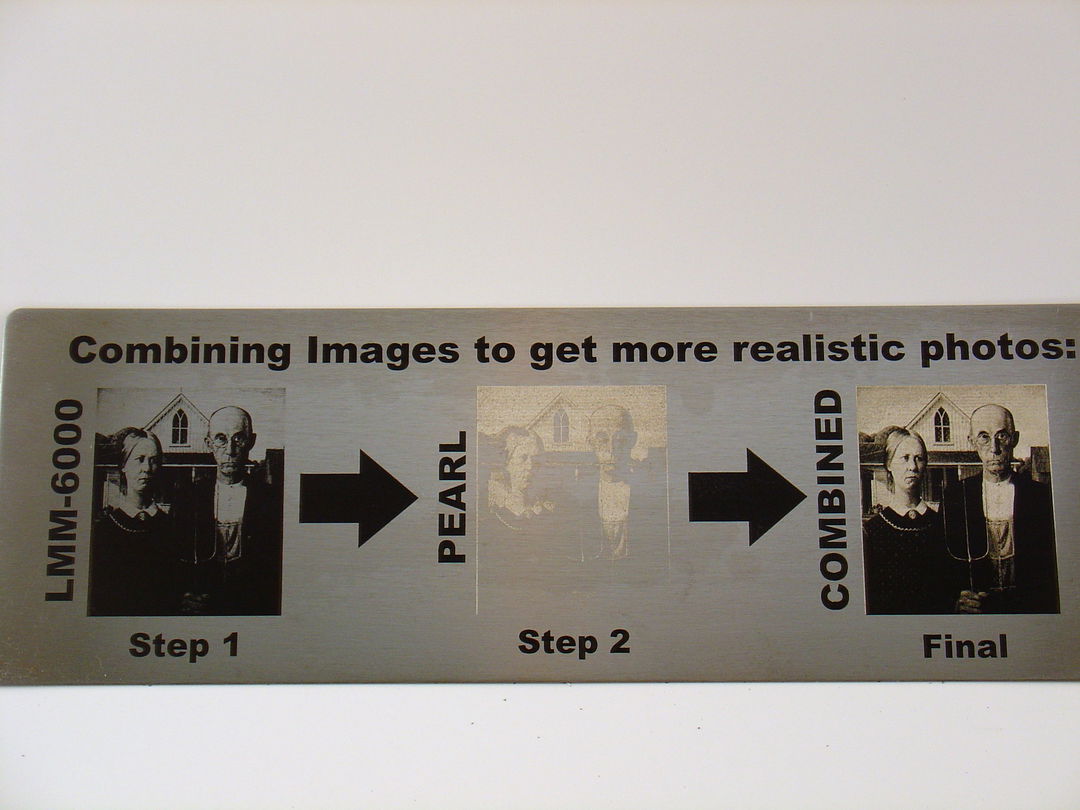

The most common problem with the CerMark process is when the mark washes off. This is caused by laser power and speed settings not being correct, the laser is out of focus or optics need to be cleaned. Every laser is different and you will have to do testing on your system to determine specific power and speed settings for each laser. Different types of metal require different power and speed settings. hard metals like stainless steel are easier to mark then softer metals like aluminum and copper. Many times brass and copper items will have a clear coating on them to prevent tarnish. These coatings prevent CerMark from bonding to the base metal. Below is an instructional video related to the use of CerMark marking materials in liquid form. Optimizing Power and Speed Settings CerMark Recommended Spray Apparatus CerMark Application from Mike Stover on Vimeo. Correct Application of LMM6000 Spray

CerMark Cup Application System – CerMark Sales

A 10% discount is given when purchasing these spray cans in quantity of 12 or more. The discount will be automatically applied at checkout., CerMark

CerMark LMM 14 black for metals spray can

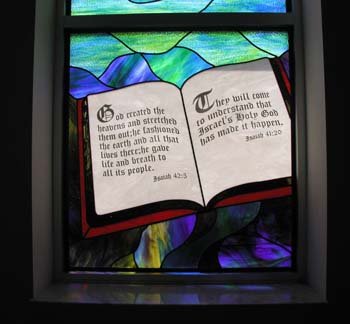

CerMark Ultra will mark at up to 80% faster speed on some laser systems compared to LMM 6000 on stainless steel. The coating will also make marks on

CerMark Ultra 12 OZ Spray Can

CerMark LMM 6018 Black Marking Tape 2 wide – CerMark Sales

CerMark Sales

Mike Stover - Owner - CerMark Sales, Inc.

Cermark Ultra Spray for Laser Marking

Lori James - Customer Support Liaison - CerMark Sales, Inc.

Morgan Cermak - National Sales Manager - Stephens Engineering Consultants, Inc.

CerMark Sales

CO2 Metal Marking Spray with a Laser

CerMark LMM 14 Black for Metals – 250 Grams Liquid – CerMark Sales