Patented Extruder Technology - Counter-rotating Twin Screw

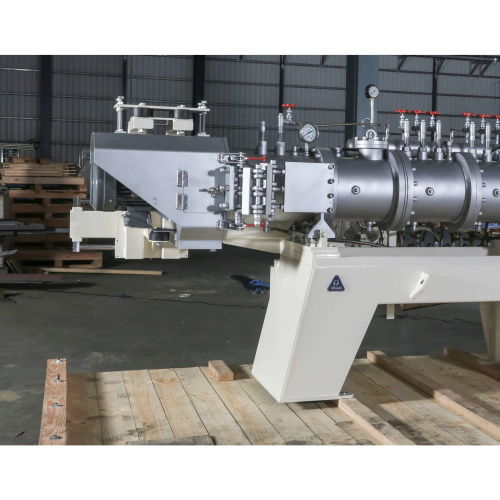

To meet new formulation challenges, a revolutionary extrusion system designed to fit the local markets was required. With a 40-year history in feed production, lDAH developed its answer: ContraTwin. lt is designed with twin-screw extrusion features but with re-engineered screw designs and rotation direction to accommodate future feed formulation. Developed to convey very sticky and puffy material (such as high fiber materials like plant protein), ContraTwin uses a very positive pump that does not waste mechanical energy or shear. For tougher materials operators can perform cooking in the mid-barrel system: this is where the actual work is done. The result of this strong pump and cooking significantly increases efficiency and utilizes low Specific Mechanical Energy (SME) when compared with other single or co-rotating twin-screw extrusions. The highest efficiency extrusion solution is therefore born. For Aqua feed Production of premium quality floating and sinking fish feed, for both fresh water and saltwater fish. The twin-screw design enables the incorporation of higher protein content in the formulation For Pet food This extruder is suitable for the production of cat food, dog food, and rabbit food, or any pet food which needs incorporation of high protein content in the formulation.

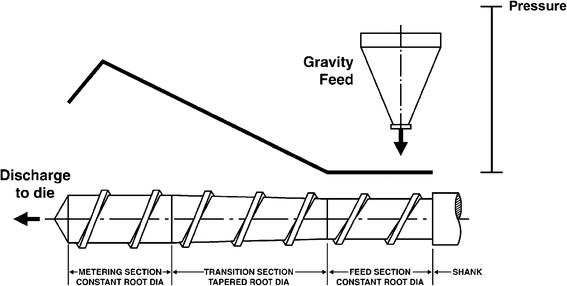

Paul Andersen, PDF, Extrusion

US20090213681A1 - Counter-rotating twin screw extruder - Google

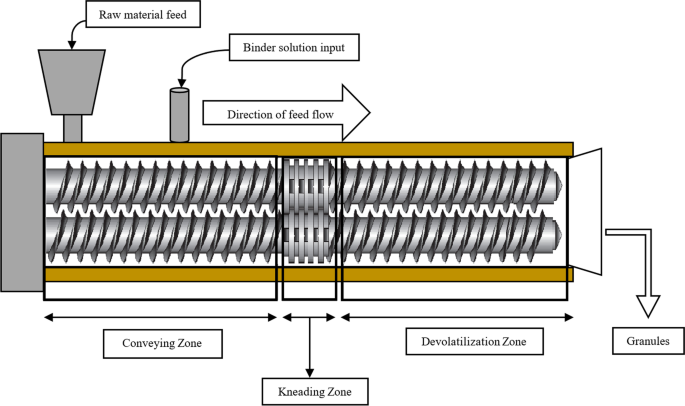

Twin Screw Extruders as Continuous Mixers for Thermal Processing

Metamorphosis of Twin Screw Extruder-Based Granulation Technology

Parallel Twin Screw Extruder, China Co-rotating Twin Screw

Co-rotating Parallel Twin Screw Extruders - Taiwan No.1 brand of

Extrusion and Expander, IDAH

Polymers, Free Full-Text

Co-rotating Twin Screw Extruder Compounding Technologies

Counter-Rotating Twin Screw Extruder Manufacturer - China Twin