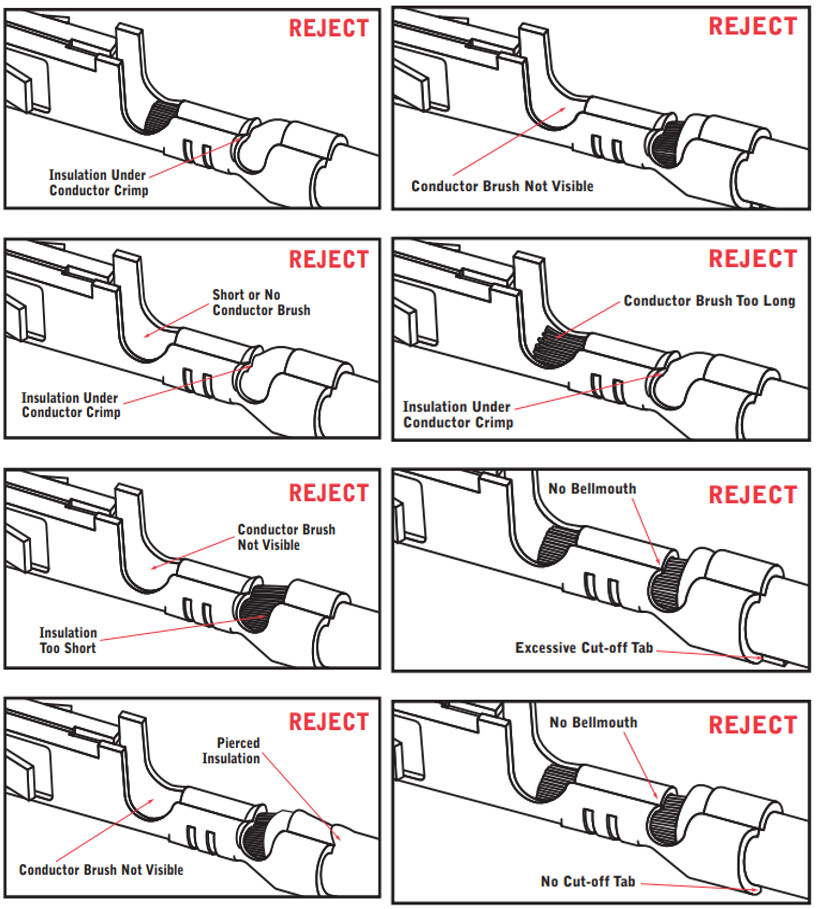

Proper Crimping: Identifying Correct Vs. Incorrect Crimps

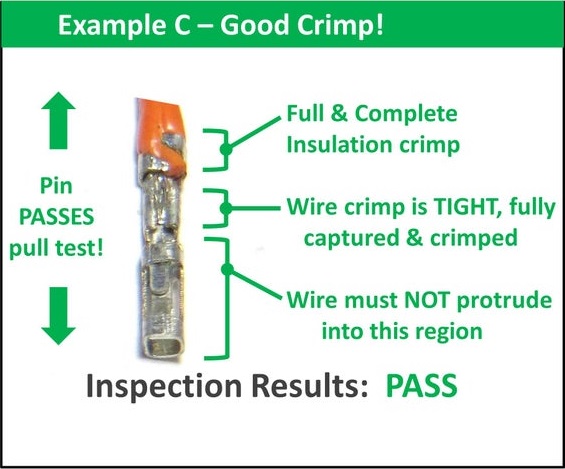

Checking crimp integrity is crucial for quality control. For large scale production, it is important to implement crimp quality checks at the start of production, throughout production, after any tooling change, and when switching to a new reel or bulk bag, as they may be mislabeled or are from a different lot code. The proper crimp tool(ing) is based on the contact being crimped, which includes manufacturer, series, and wire gauge size. Different crimpers or tooling may crimp a contact within

Bad Crimp Connection - PIEK

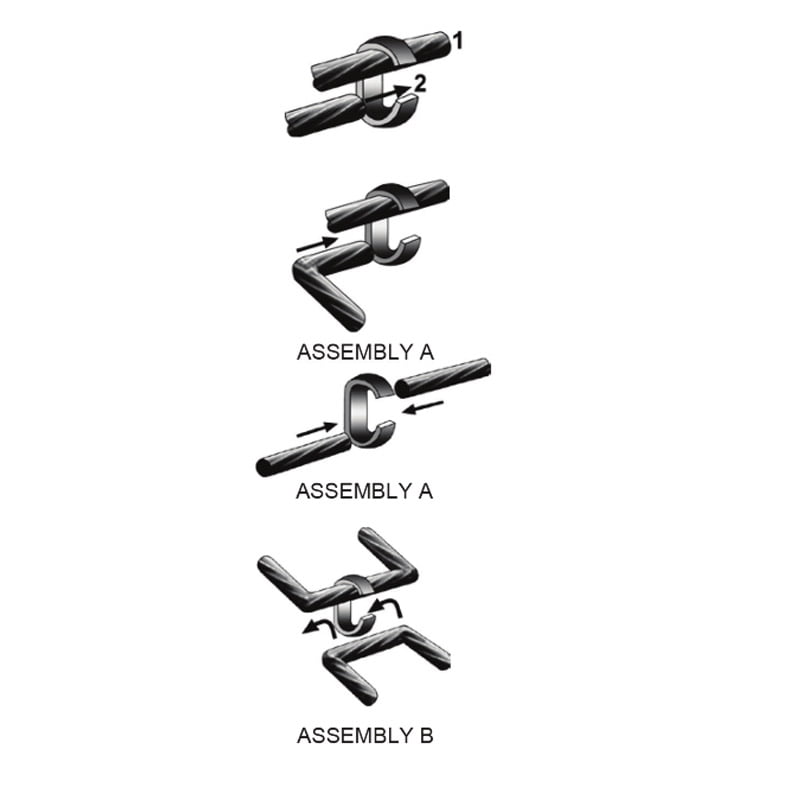

Hexagonal Crimp, Cable Lugs, Crimping Tool

DuPont and “DuPont” connectors, and how to crimp them properly – Matt's Tech Pages

Wire Crimpers 101: What is a Wire Crimping Tool? (And What to Consider Before Buying One)

Crimp (joining) - Wikipedia

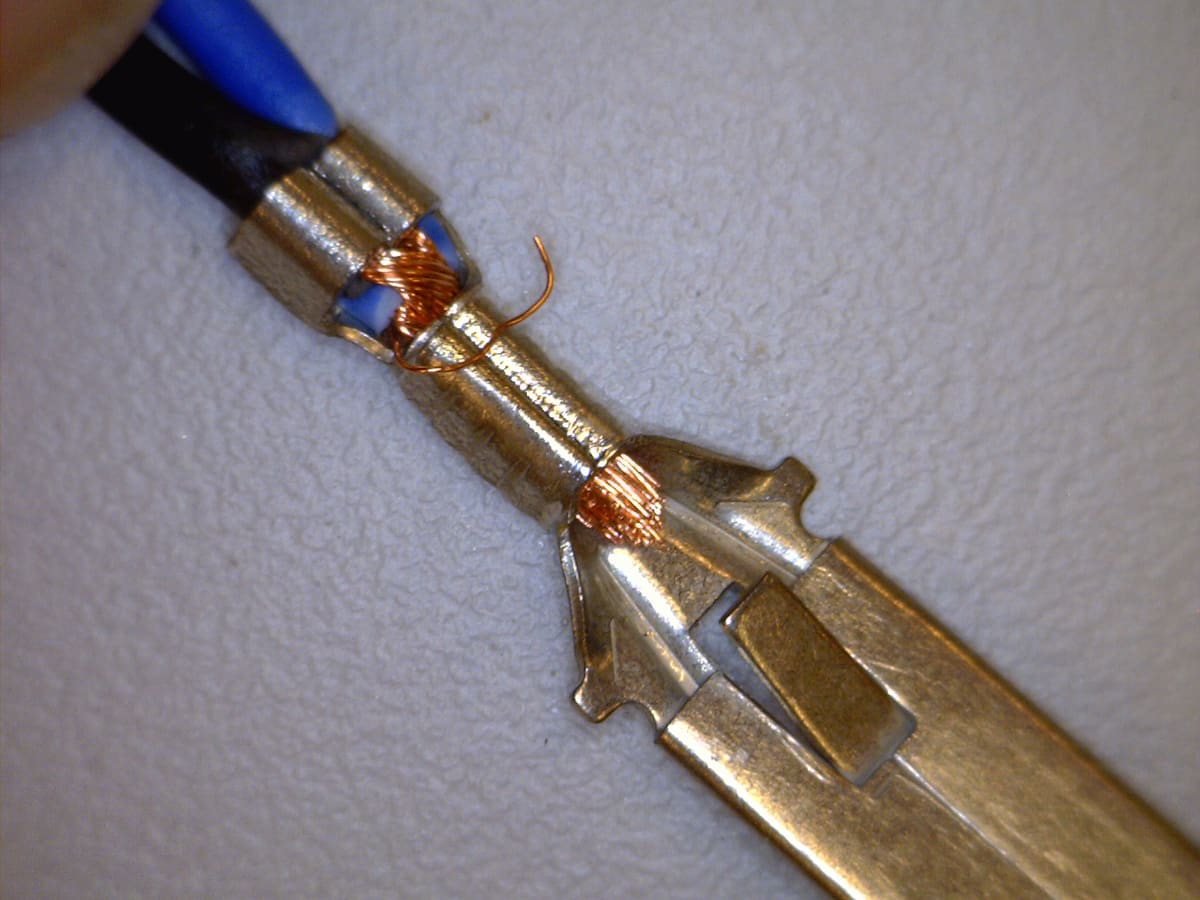

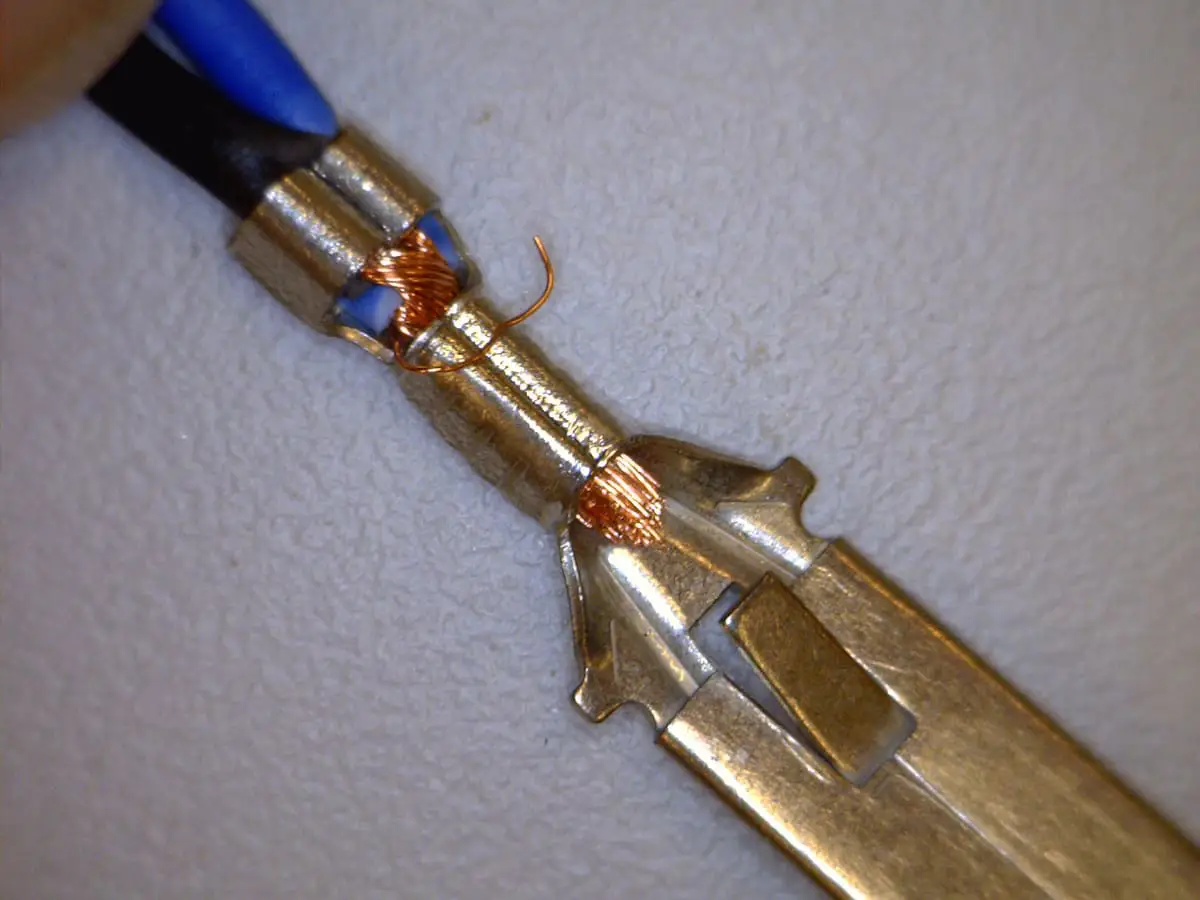

tools - Crimping Connector Issues - Electrical Engineering Stack Exchange

Wire harness dilemmas Honda CBR 600RR Forum

We dislike these crimps, because they fall off too easily. what are some better ones for connections to sparks - Electrical - Chief Delphi

Selecting the Correct Crimp Tool for terminiting connector to cable

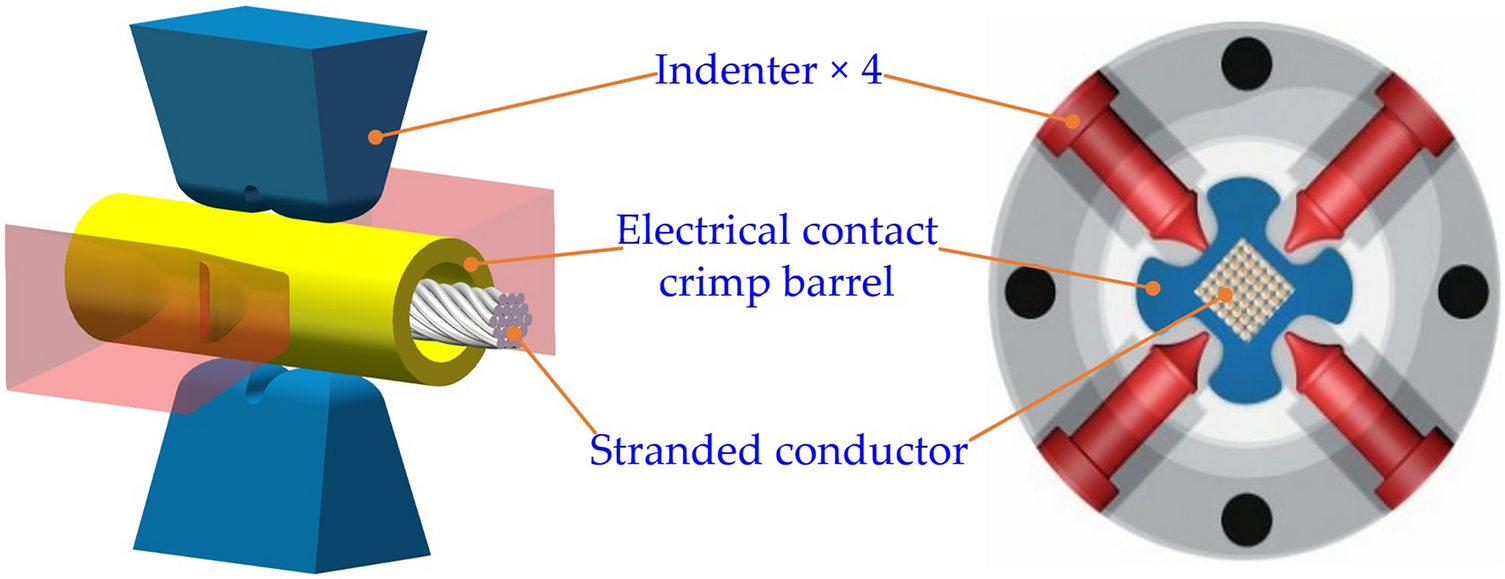

Mathematical model for the tensile strength of the crimping assembly of aviation wiring harness end

Crimp Force Monitoring – The Recipe for Success

Wire and Cable Crimpers Selection Guide: Types, Features, Applications

Inspecting crimp on connector terminals - Design Tools and Resources - Electronic Component and Engineering Solution Forum - TechForum │ Digi-Key

Numerical and experimental study on the relationship between pull-out force and indentation depth of aviation wire crimp terminal