Two reasons why ceramic tool materials can be used to machine in high-speed conditions

We will discuss 2 reasons why ceramic tools can realize significant “productivity improvement” at the manufacturing site. 1.

Why Speed, Feed, and Depth of Cut are Important Factors

Bruna Ianicelli on LinkedIn: #tiktok #short #sweet #simple #genius

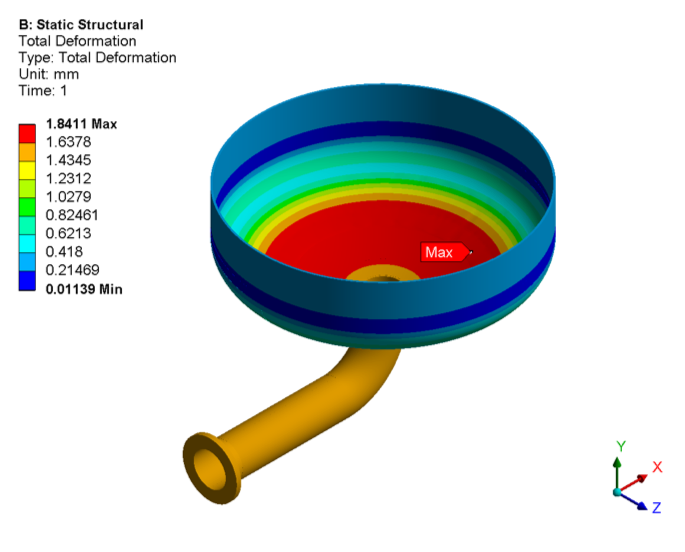

Unlocking Efficiency and Reliability: The Benefits of FEA Analysis for Nozzle Design

Ceramic cutting tools materials and examples

5 Types of Ceramic Cutting Tools & Their Uses - NEXT GENERATION

NTK Cutting Tools (Tungaloy-NTK UK) on LinkedIn: #cuttingtools #millingcutter #millingtools #milling #ukmfg…

Neil N Redpath on LinkedIn: Head-exchangeable reamer ReamMeister improves productivity for deep boring…

Neil N Redpath on LinkedIn: #aerospacemanufacturing #precisionmachining #cncmachining…

Ceramic Inserts Can Boost Turning Productivity

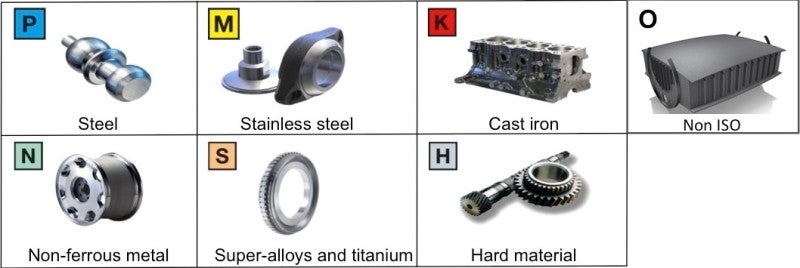

Workpiece materials

NTK Cutting Tools (Tungaloy-NTK UK) on LinkedIn: NTK - DM4 Coated Carbide Grade with AM3 Chipbreaker

Unlocking Efficiency and Reliability: The Benefits of FEA Analysis for Nozzle Design