Understanding Silk Screen Technology in Printed Circuit Board (PCB)

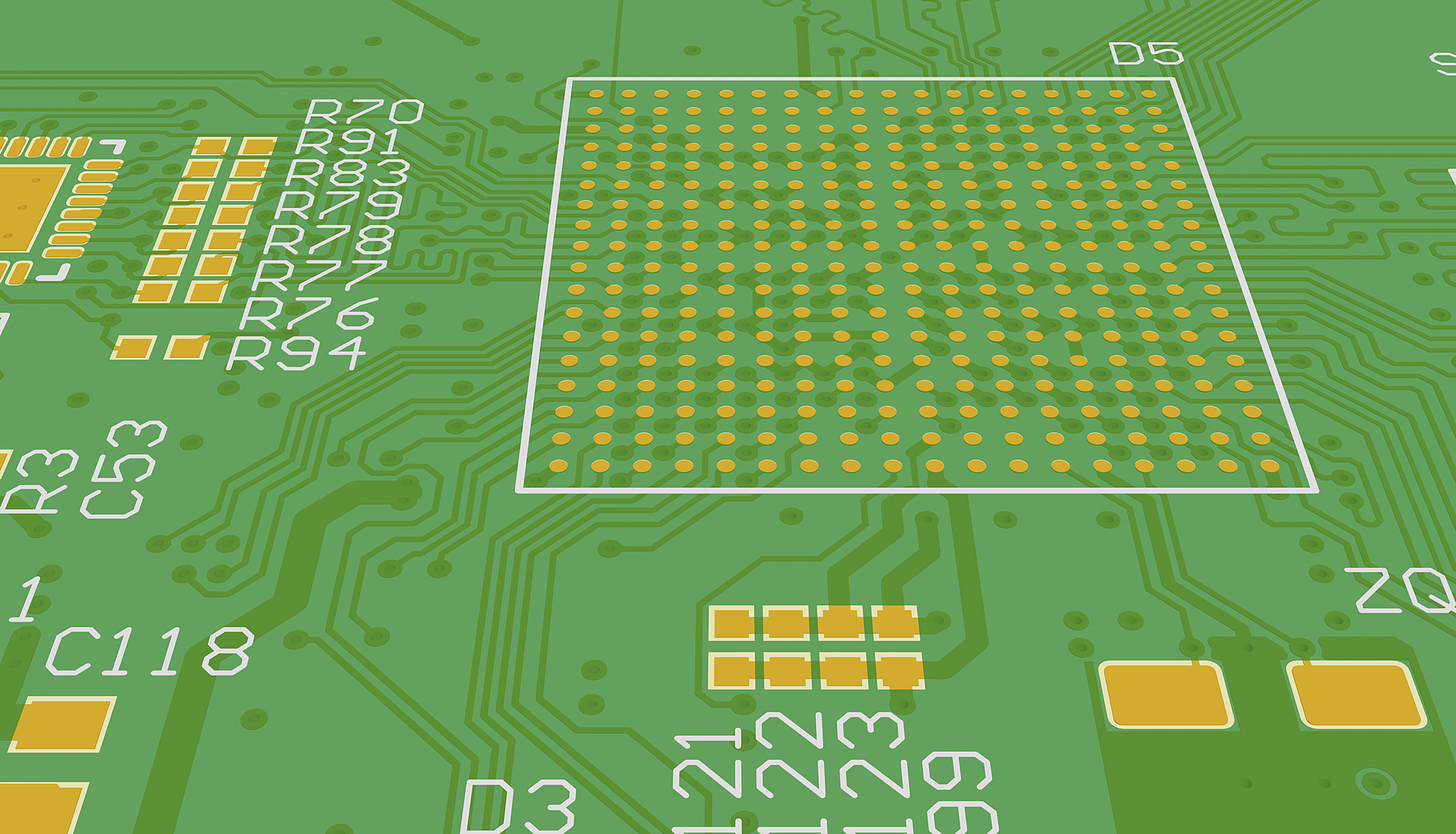

Adding the silkscreen layer onto a printed circuit board is the final step in the fabrication process. Silkscreen is a layer that uses ink traces to identify all the PCB board components, test points, parts of the PCB, warning symbols, logos and marks etc. These shapes, numbers, and letters really aren’t some new language. They can also communicate the function of each of the pins. This silkscreen is applied on the component side; all though you may find the use of silkscreen on the solder side is also not uncommon, which will increase the cost. Essentially a detailed PCB silkscreen will benefit both the manufacturer and the engineer to locate and identify all the components.

What Is Silkscreen on PCB? What's It Used For?

What is PCB (printed circuit board) and how it's made - Soldered

How RoHS-Compliant PCB Assembly Services are Different from Assembly Services?

Metal Working & Finishing

Understanding the Makeup of a Printed Circuit Board

How Yun Industrial Acme PCB Assembly uses X-ray technology, ACME PCB Assembly posted on the topic

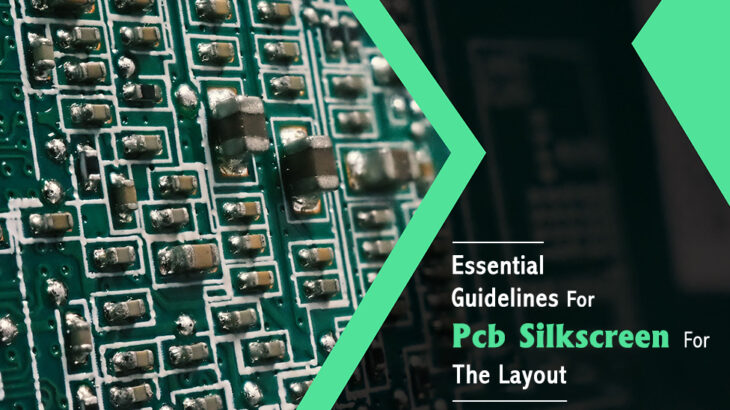

Essential Guidelines For PCB Silkscreen For The Layout

Top-Quality Silkscreen PCB by PCBTok

The Ultimate Guide to PCB Silkscreen: Process, Methods & More

Acme PCB assembly oop- (@AcmePCBassembly) / X

Richard McPeak - Yun Industrial

Silkscreen Sierra Circuits

What is Silkscreen on a PCB?